What are Cable Ties used for?

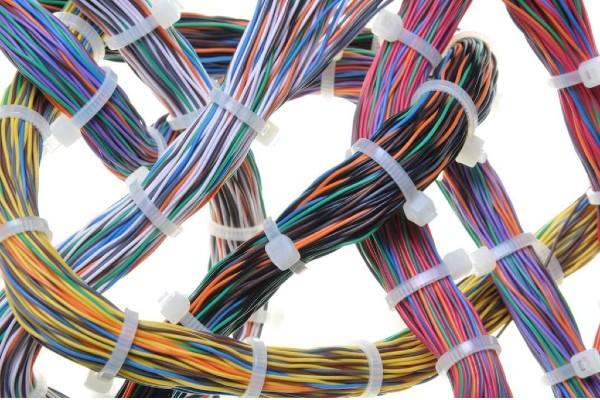

Cable ties or Nylon cable ties are used as fasteners, which helps you to bundle your cables and wires together to keep them organized and hence preventing damages. Nylon Cable Ties come in different lengths, sizes, in form of different materials and colors. The use of cable ties varies across different industries, but what they all have in common is that they are the most effective way to manage your cables.

Nylon cable tie suppliers are now into producing various types of cable ties. Here, first we are going to show you the types of cable ties available in the market. Then we will dive deep into the world of Nylon cable ties and discover the amazing features and benefits that JIGO, the largest Nylon cable tie supplier in the market offers.

Different types of Cable Ties are:

- Standard cable ties – They are:

- Self-locking.

- Usually single use.

- Are available in different colors.

- Releasable cable ties – They are:

- Reusable.

- Can be opened to add more ties.

- Available in different colors.

- Screw mount cable ties – They are:

- Ideal ties for fastening to metal or wooden panels.

- Can be used for screwing and bolting down.

- Belt cable ties – They are:

- Flexible design.

- They have a quick-release mechanism.

- Marker cable ties – They are:

- These are usually standard cable ties, but they have a tag to write on.

These are namely the 5 types of cable ties that are widely available in the Indian markets.

Related Blog: An Extensive Guide to Cable Ties

Nylon Cable Ties

Nylon is the most common material that is used for cable ties. Nylon is widely accepted by Nylon Cable Tie suppliers because they are tough materials that possess good thermal and abrasion resistance. These ties also resist fuels and most chemicals. The grade Nylon 6/6, are often used cable ties, it meets YL94 V-2 flammability ratings and has a temperature range of working from -40-degree F to 185-degree F.

Nylon cable ties have the potential to stabilize heat for continuous or extended exposure to high temperatures up to 250-degree F. Nylon cable ties suppliers can also produce UV stabilized ties for outdoor uses. To give an example here, you can have the same nylon cable tie that is manufactured for different applications.

These ties are natural and can be used for indoor purposes, whereas Black UV stabilized Nylon cable ties are often used for outdoor purposes.

Related Blog: Types Of Cable Ties To Buy

Examples of Nylon Cable Ties are:

- Heat stabilized for standard cable ties.

- Beaded cable ties.

- Double-headed cable ties.

- Marker cable ties.

Features of Nylon cable tie are as follows:

- They are recycled and recyclable.

- Nylon cable ties are durable.

- The process and materials that are used to make these Nylon cable ties are reviewed and approved by UL Environmental Agency.

The benefits of using Nylon cable ties are:

- They help to reduce waste in landfills.

- They reduce reliance on virgin nylon which is derived from non-renewable petroleum.

- These ties increase the free time. They reduce daily clutter and keeps the items in storage neat and untangled.

- They are strong, they not only does help the environment but also produce a ductile strength of 50 pounds.

These are the listed features and benefits that are offered by the Nylon cable ties suppliers.

This blog presents an overview of Nylon cable ties, which includes the types of cable ties commonly available in the market, along with their features and benefits. For more information’s regarding cable ties please contact JIGO one of the leading Nylon cable tie supplier in India at https://jigoindia.com/.